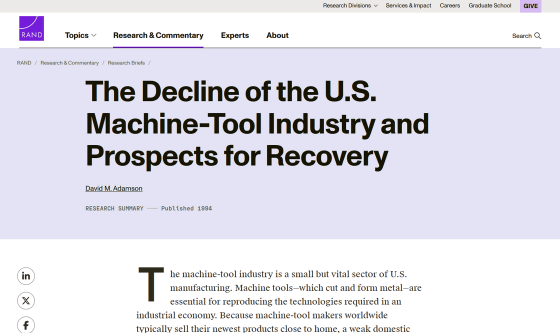

Why did the U.S. machine tool industry decline in the 1980s and 1990s? Can tariffs help solve the problem?

US President Donald Trump

The Decline of the US Machine-Tool Industry and Prospects for Recovery | RAND

https://www.rand.org/pubs/research_briefs/RB1500.html

The Decline of the US Machine-Tool Industry and Prospects for Recovery (1994) | Hacker News

https://news.ycombinator.com/item?id=43588337

Machine tools are machines that mainly make metal machines and general parts, and are also used to process wood, resin, etc. Since machine tools are used in a variety of manufacturing industries, the machine tool industry is an important element of the manufacturing industry. In general, machine tool manufacturers sell their latest products in their own country and in countries with which they have close ties, so a weakening of the domestic machine tool industry could be a risk to the entire manufacturing and defense industries.

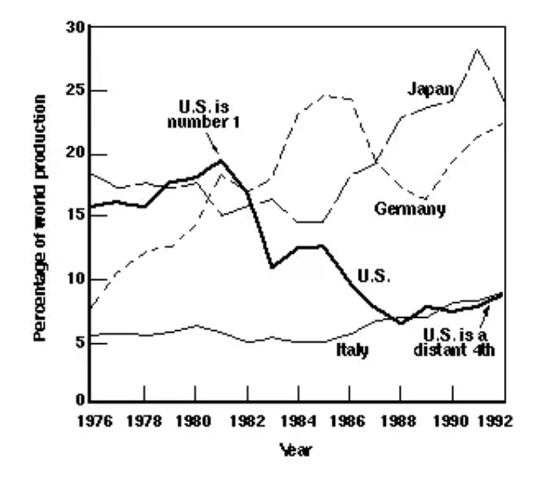

In the 1980s, the United States was the world's largest manufacturer of machine tools, but the American machine tool industry gradually declined throughout the 1980s, and by the 1990s, American machine tool production had fallen to less than half that of Japan or Germany. At the time of writing, the majority of the top machine tool market shares are held by German and Japanese companies.

The graph below shows the machine tool market share by country from 1976 to 1992. The United States, shown by the thick solid line, held the top share until the early 1980s, but was then overtaken by Japan and Germany, and as of 1992 was competing with Italy.

So,

◆ Reasons for the decline of the American machine tool industry

The analysis identified four factors that contributed to the decline of the U.S. machine tool industry in the 1980s:

1. American machine tool manufacturers were too dependent on domestic consumption and were therefore severely affected by the decline in demand from 1981 to 1983.

2. Historically, U.S. machine tool manufacturers responded to unstable demand by building up backlogs (orders received but not delivered). This allowed Japanese manufacturers to fill new orders quickly when demand recovered, while U.S. manufacturers with backlogs could not.

3) Japanese companies have surpassed American companies in terms of machine tool reliability, price, and modular production technology, significantly improving productivity and gaining first-mover advantage in the CNC (computer numerical control) market.

4) The appreciation of the dollar during this period hurt the ability of American companies to compete with foreign rivals.

While these issues help explain the factors that led to the decline of the US machine tool industry, they do not explain why the industry failed to revive itself and adapt to new markets between 1983 and 1992. Anderson argues that the failure to bounce back after the decline is indicative of more fundamental problems within the industry.

Why the industry was unable to recover

Competitive advantage in machine tools requires responding to two trends: rapid technological change and global competition, and acquiring new capabilities as needed. Anderson speculates on why American machine tool manufacturers have not been able to acquire new capabilities:

First, America has too few large companies to develop the capabilities necessary to compete globally, including investments in capital goods, worker training, marketing for exports, and other areas, and it lacks mechanisms to generate cooperation among small and medium-sized businesses.

2: American machine tool manufacturers have a hard time raising capital due to high transaction costs, lack of long-term banking relationships, excess production capacity, and low profitability. This makes it hard to buy new machinery and spend money on marketing. In contrast, foreign companies are given government incentives to invest in advanced industrial equipment.

3) American workers have lower skills than their counterparts abroad due to weak basic qualifications, a collapse of apprenticeship systems to produce skilled workers, and a shortage of graduate engineers. Labor market structure and a poor track record of government training programs have combined to discourage investments in worker training, as has been the case in Japan and Germany.

4. The United States leads the world in basic technological research related to machine tools, but weak connections between universities and machine tool manufacturers have hampered efforts to translate that technology into market advantage.

5. American manufacturers have been slow to adopt new technology in order to build machines. The only exception is the defense industry, where American machine tools remain competitive in the market.

6. Global demand for machine tools surged in the late 1980s, but U.S. machine tool manufacturers were unable to capitalize on this opportunity due to their lack of export orientation. The ability of U.S. machine tool manufacturers to export has been hampered by lengthy export licensing procedures, government regulations governing defense-related technologies, and a lack of government support for exports.

Is there any prospect of recovery?

Anderson pointed out that although American machine tool manufacturers are struggling due to various obstacles, they are benefiting from factors such as domestic corporate restructuring, a surge in domestic demand, and the economic crises of rivals Germany and Japan. Furthermore, he predicted that Japan's advantage in CNC technology is also wavering, and that the United States, which leads in basic research, may be able to make a comeback in the machine tool market in the future.

What role should the government play in helping to rebuild the country?

To revive American machine tool manufacturers, Anderson concluded that the government must play the following roles:

1: Support the creation of regional cooperation networks between machine tool manufacturers, users and suppliers to encourage the adoption of new technologies. By building a network of companies, they can offer a package of services that would not be possible for any one company to offer on its own.

2: Increase investment in manufacturing infrastructure (such as applied research and metalworking technologies that can be used for machine tools), direct federal research and development toward improving production processes, and build closer relationships between research institutions and companies.

3. Help American machine tool manufacturers compete internationally by further streamlining export licensing procedures, supporting international sales efforts, and avoiding the protectionist policies of the past. A global presence is essential for American machine tool manufacturers to thrive in the long term.

Thus, the 1994 report recommended that in order for machine tool manufacturers to prosper, it was important to grow the domestic industry while maintaining an international presence, rather than resorting to protectionism such as raising tariffs.

At the time of writing, American manufacturing was being weakened by foreign products, and the Trump administration was elected with the support of manufacturing workers and business leaders. However, the Trump administration's policies are the exact opposite of those recommended in the 1994 report, and it has raised tariffs to protect the manufacturing industry.

Problems such as falling stock prices and rising prices have already emerged, but U.S. Trade Representative Jamison Greer has said that 'some pain is necessary to bring manufacturing back home.'

Related Posts:

in Note, Posted by log1h_ik