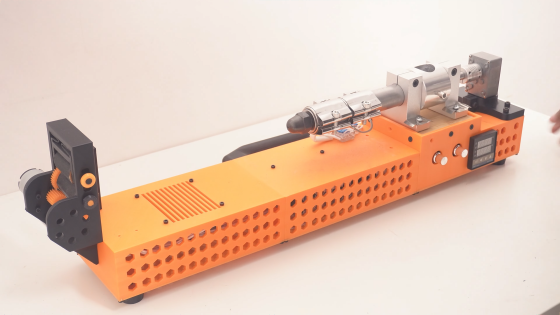

ExtrudeX turns 3D printing waste into reusable filament

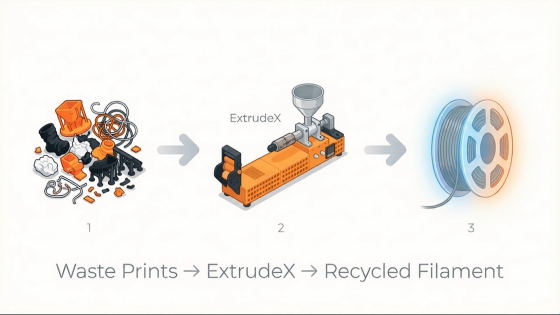

One of the problems with using 3D printers is that support materials, failed parts, unnecessary test models, etc. tend to accumulate as waste. A device called ' ExtrudeX ' has been released that turns this plastic waste from 3D printing into a form that can be used again as filament at home.

The 'ExtrudeX' machine wants to turn your 3D printing waste into reusable filament, all at home — this Kickstarter project is itself 3D-printable with minimal hardware costs | Tom's Hardware

You can get a good idea of what kind of device 'ExtrudeX' is by watching the video below.

ExtrudeX: A 3D printing machine that recycles discarded 3D prints into filament - YouTube

3D printers produce waste.

Wouldn't it be great if we could turn that waste back into filament?

This 'ExtrudeX' makes this possible

First, waste such as failed pieces and support materials is crushed into small pieces.

Once crushed, it is mixed with new plastic (virgin material) pellets.

The recommended ratio is 60% new plastic and 40% crushed and pelletized waste.

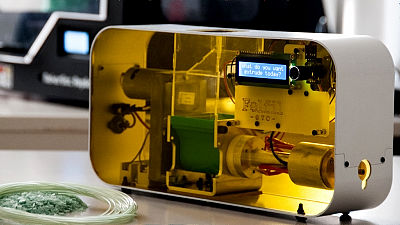

Turn on the power.

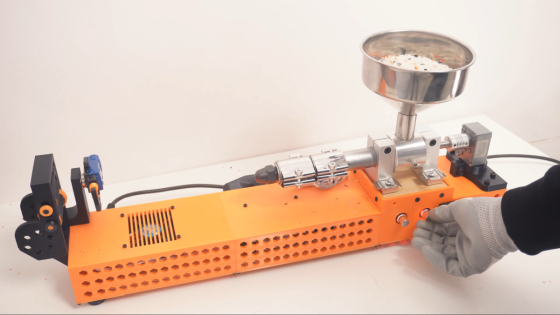

Set the temperature with the temperature controller.

Put the mixed pellets into the hopper on the right.

Operate

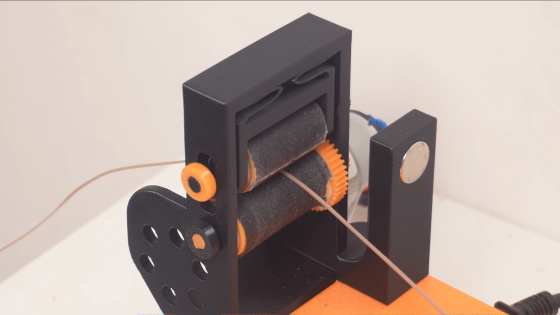

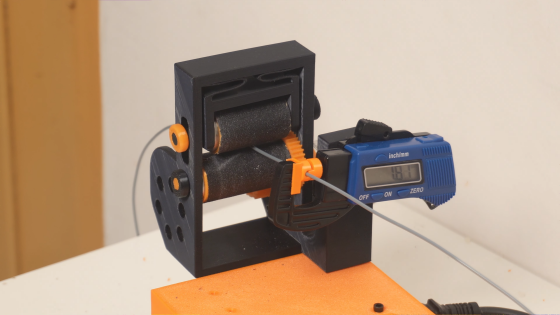

The pellets pass through a barrel that is stirred internally, where they are heated and extruded from the nozzle on the other side. Because the filament is soft immediately after being extruded, you will need to first grab the thread with tweezers or something similar and pass it to the puller (a device that pulls the filament) on the other side.

Once the filament is hooked onto the puller, the puller will automatically continue to pull the filament.

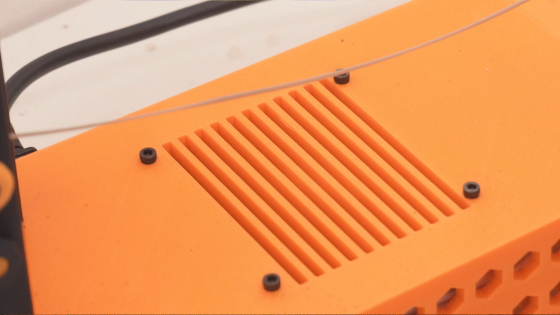

A cooling fan is placed between the nozzle and the puller to quickly cool and harden the filament.

It is also possible to attach a digital dial gauge to monitor the filament length in real time.

All you have to do is keep feeding the pellets in. The ExtrudeX melts the pellets and forms them into filament, and the puller continues to pull out the filament until you have a spool full for collection.

The ExtrudeX has a carry handle on the side, making it easy to carry around.

'ExtrudeX' is currently seeking investment on the crowdfunding site Kickstarter . At the time of writing, more than 2,400 investors from around the world have contributed approximately $181,700 (approximately 28.32 million yen) to the target amount of $2,000 (approximately 310,000 yen).

At the time of writing, it is possible to get a 'complete set of blueprints such as the STL file and component list of' ExtrudeX 'with a contribution of $ 49 (approximately 7,600 yen). Also, with a contribution of $ 69 (approximately 10,700 yen), in addition to 'a complete set of blueprints such as the STL file and component list of' ExtrudeX ', you can get the 'STL file of' PETFusion 2.0 'that can make filaments from PET bottles. ' Furthermore, with a contribution of $ 109 (approximately 17,000 yen), you can get a commercially available version of 'a complete set of blueprints such as the STL file and component list of' ExtrudeX ', and with a contribution of $ 129 (approximately 20,100 yen), you can get a commercially available version of 'a complete set of blueprints such as the STL file and component list of' ExtrudeX ' and 'PETFusion 2.0 '.

The deadline for investment is 11:32 pm on Thursday, January 1, 2026, Japan time, and shipping is scheduled for around January 2026.

ExtrudeX – 3D Printable Filament Recycler & Maker by Creative3DP — Kickstarter

https://www.kickstarter.com/projects/creative3dp/extrudex-3d-print-waste-recycler-and-filament-maker/

Related Posts: