Researchers successfully reuse mosquito mouthparts to create ultra-fine nozzles for 3D printers, potentially leading to the production of transplant organs

A Canadian research team has developed a technology that uses mosquito mouthparts to create ultra-fine nozzles for 3D printers.

Science Advances DOI: 10.1126/sciadv.adw9953

Mosquito proboscis repurposed as ultra-precise 3D printer nozzle

https://www.newscientist.com/article/2461196-mosquito-proboscis-repurposed-as-ultra-precise-3d-printer-nozzle/

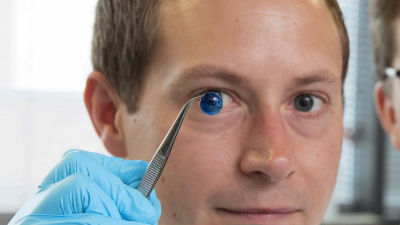

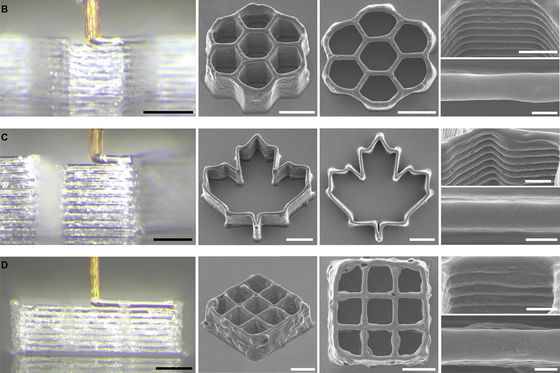

Professor Changhong Cao and his research team at McGill University in Canada have developed a unique technique for reusing severed female mosquito mouthparts as 3D printer nozzles to fabricate extremely tiny structures. This technique is called '3D necroprinting.' The research team was motivated to develop this technique by the limitations of commercially available 3D printer nozzles. The smallest commercially available nozzle has an inner diameter of 35 micrometers and costs as much as $80 (approximately 12,000 yen). The research team tried other methods, such as glass drawing, but these nozzles were expensive and extremely fragile.

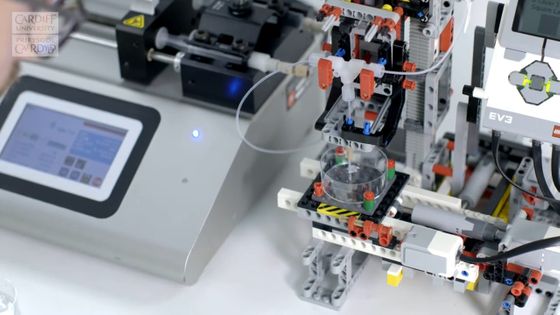

The research team tasked graduate student Justin Puma with investigating a variety of natural organs, from scorpion stingers to snake fangs. They ultimately discovered that the mouthparts of female Aedes aegypti mosquitoes were ideal for printing ultra-fine structures measuring just 20 micrometers. According to Chanhong Cao, once a worker masters precise cutting and extraction of female mosquito mouthparts under a microscope, they can produce six nozzles from the mosquito mouthparts per hour for less than $1 (approximately 155 yen). This process is easily scalable and can be easily attached to existing 3D printers. Considering their biological origin, they have a relatively long lifespan—about 30% begin to break down after two weeks—but can be frozen and stored for up to a year.

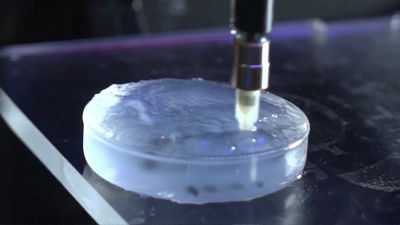

Examples of using organs from small organisms as mechanical parts include drones that use moth antennae to detect smells, and necrobots that use spider corpses to create robotic hands . The research team believes that 3D printing using bioink ' Pluronic F-127 ,' which can build scaffolds for biological tissues including blood vessels, is a promising method for manufacturing artificial organs.

'This research is a good example of human engineers struggling to catch up with nature's tools,' said Christian Griffiths of Swansea University in the UK. 'It took 2 million years for mosquitoes to evolve, so perhaps nature has a better technology than we do.'

Related Posts: