Microgravity could become a new frontier in pharmaceutical medicine

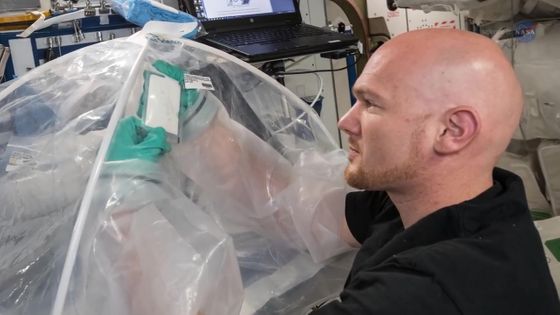

Varda Space Industries, an American space research company, is working to manufacture new medicines in space that cannot be produced on Earth. Varda Space Industries claims to be the first private company to successfully synthesize a medicine in space and bring it back to Earth intact, demonstrating that the crystallization process that occurs in microgravity is maintained even after returning to Earth's gravity.

Microgravity Is The Final Frontier For Medicine. Here's Why. : ScienceAlert

How Varda Makes Pharmaceuticals in Orbit - YouTube

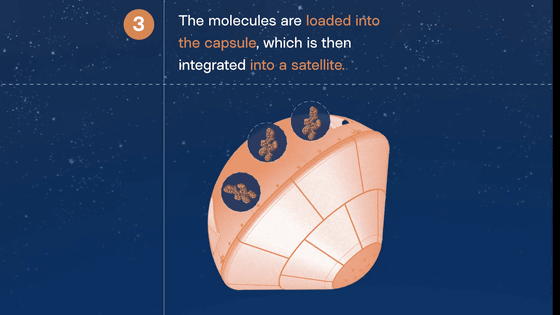

On May 13, 2025, the company's third spinning top-shaped capsule, W-3 , completed its two-month role as a laboratory in low orbit, re-entered Earth's atmosphere from space, and landed in the Australian desert.

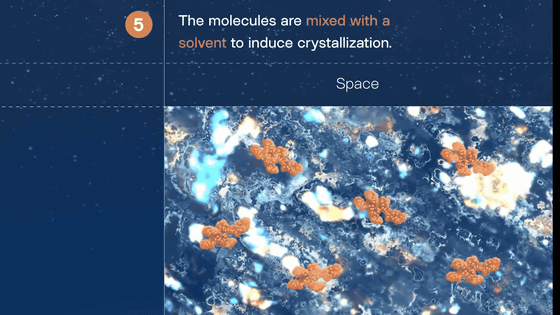

Adrian Ladocere, chief scientific officer at Varda, said the crystalline structures formed in microgravity may differ from those formed on Earth, even for the same active pharmaceutical ingredient. These structural differences could have a variety of implications, including improving drugs and enabling new routes of administration.

On Earth, gravity can affect the crystallization of small molecules, causing them to aggregate and grow unevenly. Furthermore, convection currents generated by gravity can agitate the liquid as the crystals form, creating further instabilities. However, experiments conducted over the past few decades on parabolic flights and the International Space Station have shown that a microgravity environment stabilizes the crystallization process and eliminates the effects that lead to uneven growth.

'Microgravity suppresses phenomena like convection and precipitation, resulting in crystals that are more uniform in size and structure,' says Lassedore. 'While gravity has little effect on the chemical reaction itself, it plays a major role in the fluid dynamics of crystallization and its dynamics at the manufacturing scale. Therefore, utilizing a microgravity environment has the potential to fundamentally change how pharmaceuticals are manufactured.'

Being able to precisely control the initial stages of crystallization and growth can affect the particle size distribution of crystals, control the state of different crystalline structures of the same component, particle shape, and purity, which has broad applications in everything from small molecule drugs to the development of active pharmaceutical ingredients for biological products, explains Raseda.

While the idea of molecular manufacturing in space is not new, it was thought that large-scale realization was impossible until the development of reusable commercial rockets. The first capsule, '

'Recently published studies on high-gravity conditions have yielded some unexpected results. The most significant finding is that gravity influences particle size even in agitated liquids,' says Lassedore. The results also suggest that the competition between sedimentation forces and concentration gradients tends to become more complex as gravity increases.

The Varda Space Industries team plans to continue their research, focusing on molecules that are known to have difficulty crystallizing on Earth, in order to find new routes to medicines that cannot be synthesized on Earth. At the time of writing, the fourth capsule, W-4 , is in orbit, with W-5 and W-6 scheduled for launch in early 2026.

In September 2025, Varda Space Industries announced a partnership with Australian launch services company Southern Launch to land 20 capsules at the Koonivah Test Site in the South Australian desert by 2028. 'We plan to administer space-produced medicines to humans within the next decade,' said Rasedore. Varda Space Industries aims to increase the frequency of launches and returns over the next few years, eventually returning capsules to Earth monthly or more frequently.

Related Posts: