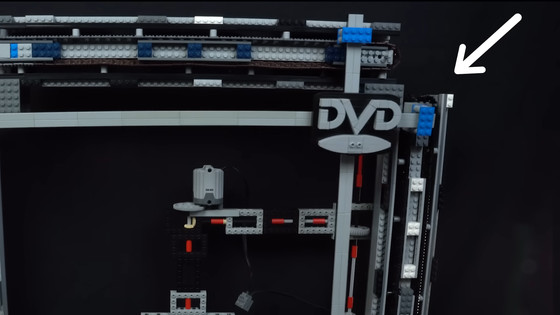

A moving DVD logo screensaver made with Lego

Some DVD players have a screensaver that displays a bouncing 'DVD' logo on the screen when the player is in standby mode and no DVD is inserted, in order to prevent burn-in to the screen of a CRT television. Lego-building YouTuber Grant Davis has recreated this bouncing DVD logo screensaver using Lego.

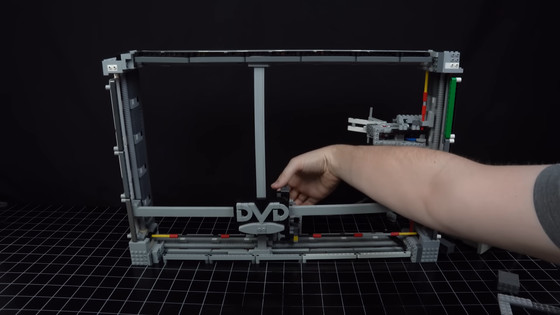

Davis started the project with the idea of recreating, in a physical machine, the screen saver he once saw on television, where the DVD logo bounces off the edge of the screen.

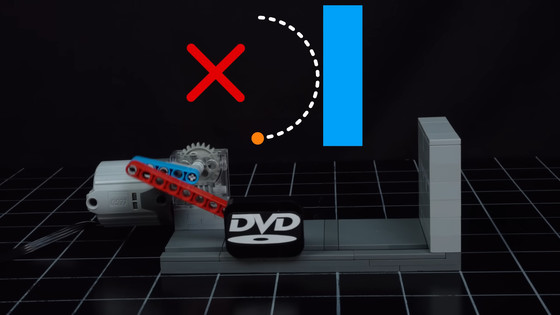

First of all, it was difficult to make the logo move towards the wall at a constant speed and then immediately reverse direction when it hit the wall. Using a circular drive gear created fluctuations in the movement, resulting in a movement that slowly approached the wall and then returned.

To control the up/down and left/right movement, they considered a method that uses caterpillar-like belts called 'treads' to move at a constant speed on flat sections and reverse using a mechanism when it hits a wall.

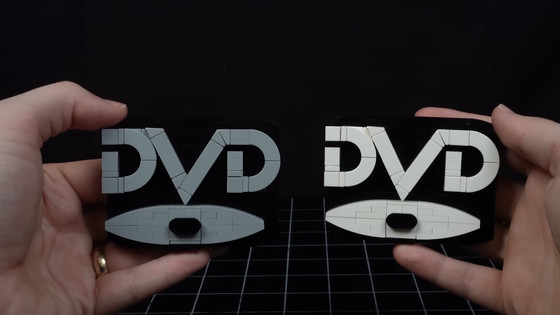

At the same time, the DVD logo was modeled out of LEGO, and a prototype was created using curved slopes, round tiles, slopes, etc.

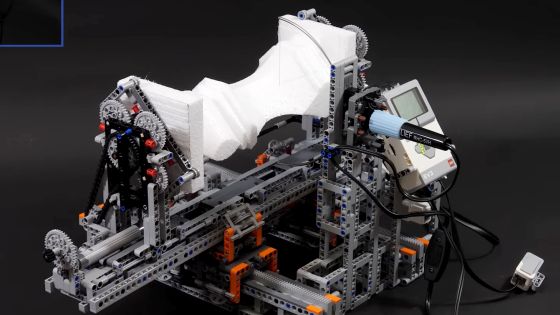

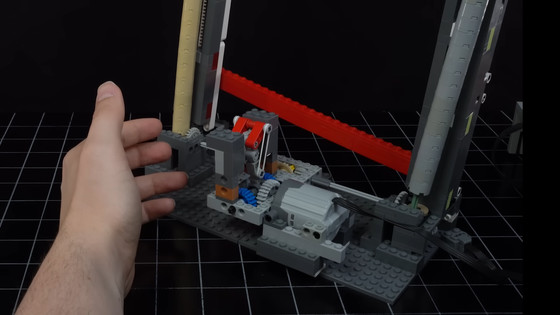

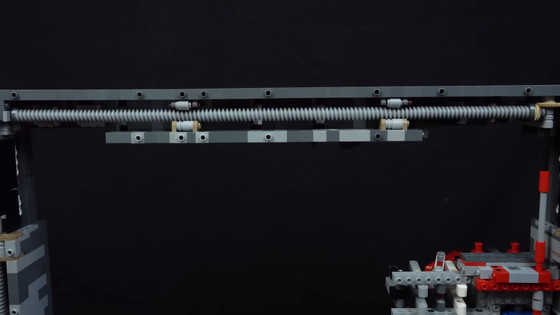

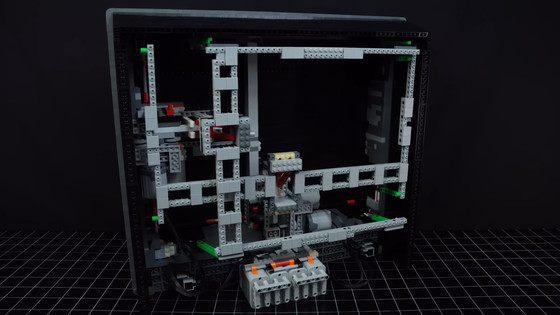

A framework is constructed to mount the treads. The top, bottom, left and right drive shafts are connected by long axles, and one motor drives the vehicle in all four directions.

However, the tread system did not bounce well, and instead of bouncing, it would often hit a wall, stop, and then bounce back.

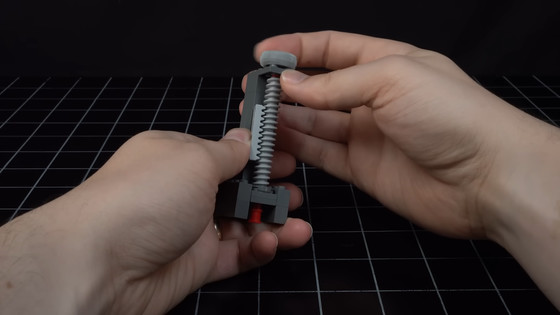

For this reason, Davis abandoned the tread system and adopted a screw shaft called a worm gear. Using a structure in which a round gear moves one tooth per rotation of the screw shaft, he aimed to achieve constant speed movement and instantaneous reversal. However, worm gears had the limitation that they could only rotate in one direction.

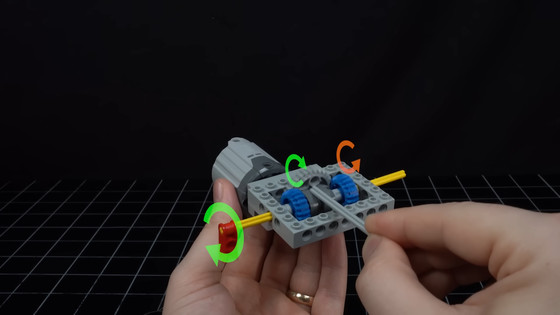

Therefore, in order to change the direction of rotation, we designed a gearbox to switch gears and reverse the drive direction.

In addition, we aim to be able to switch gears at any time by using a rubber band as an aid.

Friction between the rubber band and gears can cause problems such as snagging or the frame breaking.

So we tried a method that uses a LEGO switch to enable 'stop/forward/reverse' while still driving the motor. This method worked relatively well, but when the switch is flipped, it goes 'off' for a moment, which causes a slight delay before the motor stops. This stop at the time of switching slightly reduces the tempo of the bounce, which became an issue.

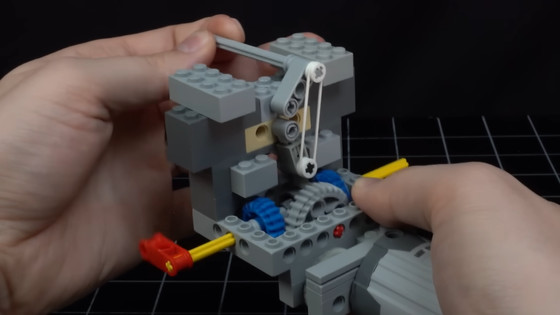

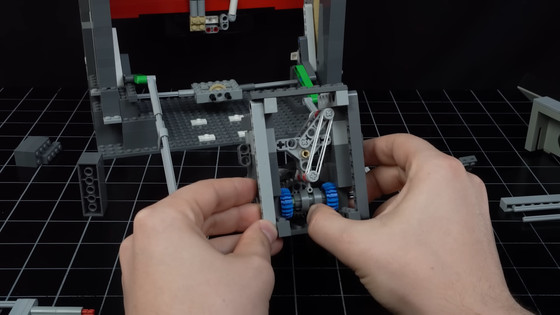

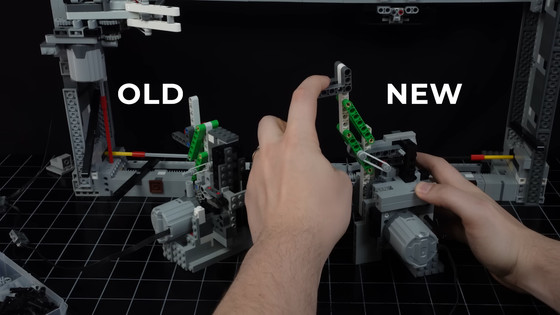

To eliminate this delay, Davis improved the switch to a physical lever. When the bar supporting the logo reaches the top, bottom, left, or right edge, its kinetic energy is used to activate a lever that presses a switch, instantly reversing the direction of the motor's rotation. To ensure the lever's strength, he combined multiple parts and adjusted the repulsive force of the rubber band to fine-tune the delicate timing.

The levers and supports are subjected to heavy loads, causing the shafts to bend, so the frame is also reinforced.

The top, bottom, left and right frameworks are constructed with an aspect ratio that mimics a 16:9 television screen, and the plates are arranged vertically to further increase strength.

We also repeatedly fine-tuned the lever position and toggle reaction angle so that the trigger would activate and flip the switch the moment the logo hit the edge.

The gearbox design proved particularly challenging. It turned out that the rubber band used to shift gears not only pulled the lever back, but also struck the frame downwards with recoil, with the kinetic energy being absorbed by the gearbox itself. This meant that the repulsive force wasn't being used to shift gears. Davis then redesigned the gearbox to redirect the rubber's repulsive force sideways, instead using it directly for gear shifting. This made gear shifts 100% accurate and instantaneous.

The basic structure is now complete. We tested it and confirmed that the logo bounced smoothly. Along with the expansion of the frame, we redesigned the gear units at the corners and increased the rotation speed of the worm gear. Furthermore, we placed an independent motor for each toggle, making the structure easier to disassemble and repair.

Additionally, a stabilizing plate has been added to the outer periphery to prevent shaking during high-speed operation.

The panel that recreates the black background was also made from Lego.

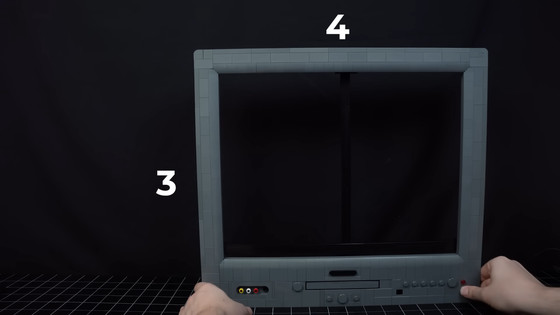

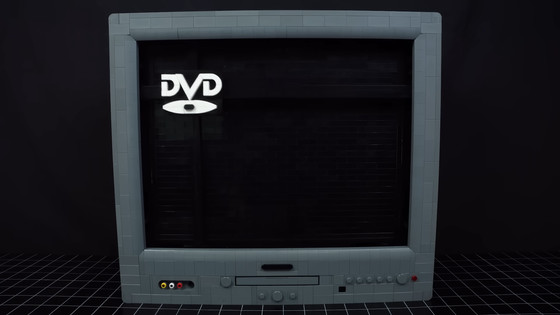

In order to recreate the look of an old CRT television, the frame's aspect ratio was readjusted to 4:3, and the front cover was also completed.

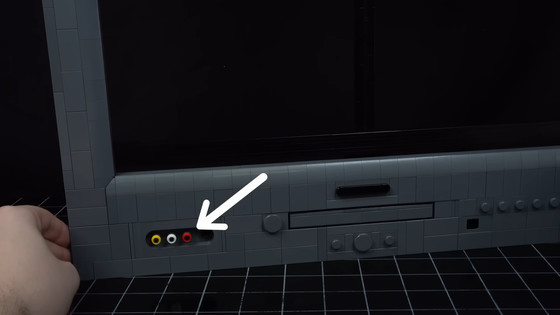

The yellow, white, and red RCA terminals are also reproduced.

The bar supporting the logo is also black, making it appear as if the logo is floating in the background.

The logo has also been updated from gray to white.

The outer frame of the TV is attached to the frame.

And there you have it: the DVD logo bounces around the TV screen in perfect time, just like the real thing.

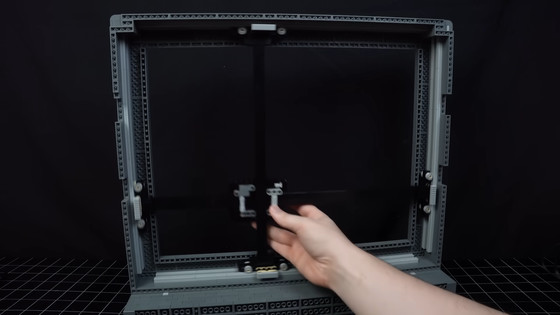

This is what it looks like from the back.

Just as the logo was about to hit the corner, Davis, who was watching, let out a loud 'Whoa!'

Related Posts:

in Video, Posted by log1i_yk