What were the results of a CT scan that revealed the problems with the recalled Anker mobile battery?

Mobile battery manufacturer Anker

What Went Wrong Inside These Recalled Power Banks?

https://www.lumafield.com/article/what-went-wrong-inside-these-recalled-power-banks

Recalled Anker Lithium-Ion Power Bank

https://voyager.lumafield.com/project/fd056b32-89ac-448c-864c-92cfe535497f

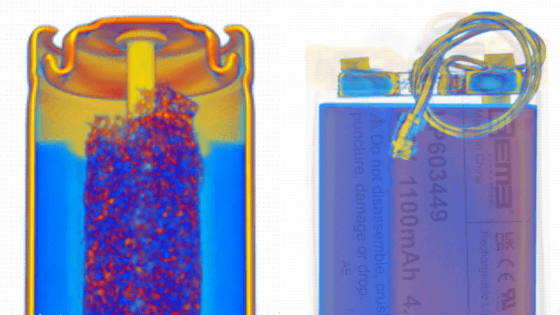

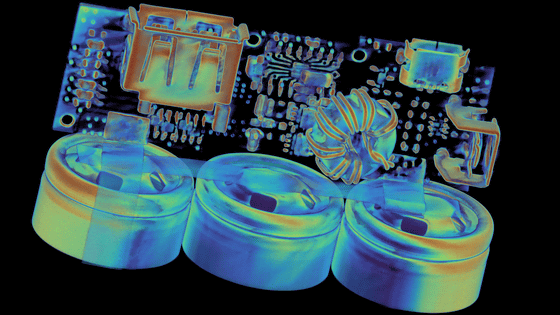

Lumafield first compared the battery cells. The PowerCore 10000 contains three 18650 lithium-ion battery cells, and the five units examined contained battery cells from at least two different suppliers. Of the five units examined, three were subject to recall, and one of them had two different characteristics from the other four.

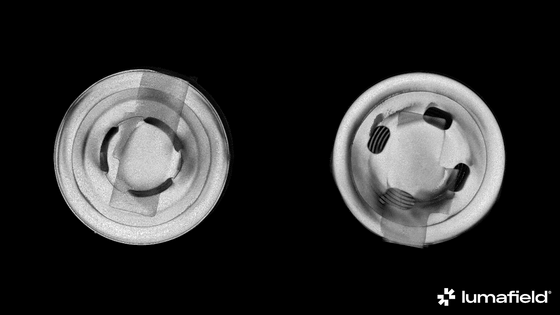

One of the batteries had a reinforcing material called a mandrel to prevent the core from collapsing if the center dents.

Additionally, the battery in question had three large vent holes on the positive side, while the other four had four small vent holes.

These differences strongly suggest that the PB3 battery is from a different supplier than the other products. However, since the recall covers products with battery cells from multiple suppliers, Lumafield argued that the root cause of the recall may lie in other parts of the power bank, rather than the battery cells themselves.

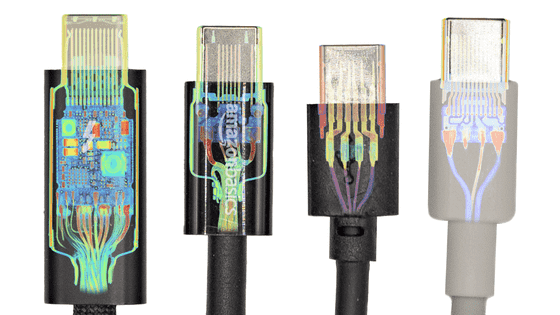

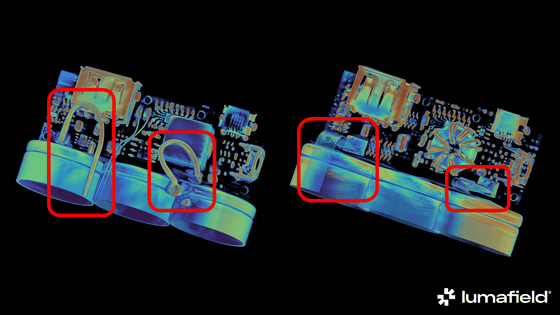

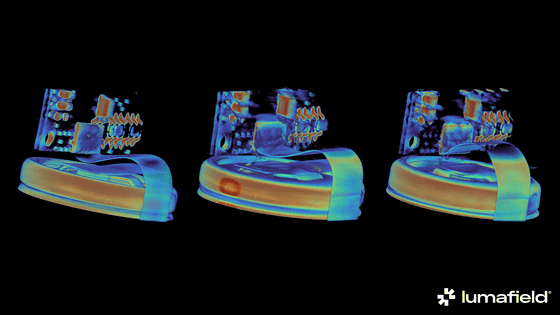

Lumafiled then compared the printed circuit boards (PCBs) and quickly found clear differences in assembly between the recalled and non-recalled products.

All five of the units surveyed had a bus bar connecting the positive and negative terminals of the 18650 battery cells. However, the two units not subject to the recall (left) used a conventional insulated wire to connect the bus bar to the PCB, while the three units subject to the recall (right) connected the bus bar directly to the PCB.

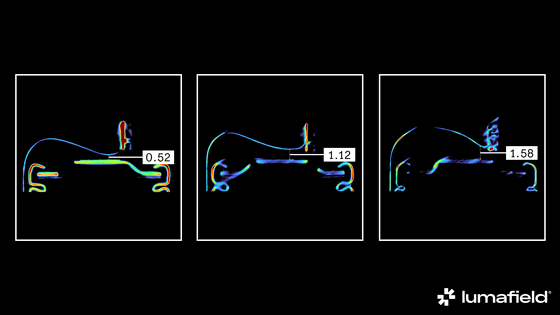

Furthermore, a closer look at the connections of the three recalled units revealed manufacturing variations that could raise concerns: in particular, the shape of the busbar that connects to the negative pole varies significantly from unit to unit, and one unit examined was found to be slightly twisted.

Below are images of the connections between the PCB and the battery cells in the three recalled units. The wavy part is the negative bus bar, and the flat part underneath is the positive bus bar. In particular, in the battery cell on the left, you can see that the negative bus bar is slightly twisted.

In addition, it was discovered that the distance between the positive and negative bus bars in the three recalled units was too short, which could lead to a short circuit if the bus bars are deformed.

>

According to Lumafield, if the anode (negative electrode) of a lithium-ion battery is not far enough away from the cathode (positive electrode), dendrite formation can cause performance degradation, short circuits, and in the worst case, thermal runaway. Thus, there are some defects in the battery manufacturing process that can be easily detected by CT scans, Lumafield said.

'The CT scan of the PowerCore 10000 provides a glimpse into the complexities of the supply chain of these seemingly simple products. Although this is a limited analysis of five power banks, a small portion of the millions produced over three years and 10 months and sold over six and a half years, we found that at least two different battery cell types and two different battery connector designs were used throughout the A1263's production lifespan. Increasing the sample size may reveal further differences,' said lumafield.

While it is not clear whether the tab bar problem discovered this time is directly related to the reason for the recall, Lumafield said, 'Managing a mass-produced battery supply chain is inherently difficult, and quality assurance at every stage is essential. Although we do not know exactly what defect triggered this large-scale recall, it clearly shows how costly quality issues can be. The production volume of these consumer products is huge, and it is extremely difficult to trace quality issues upstream.'

Related Posts:

in Free Member, Hardware, Posted by log1i_yk