Details of Apple's lab where it tests iPhones and iPads for durability revealed

At

The Unseen Grind: A Visit to Apple's Durability Lab

https://www.counterpointresearch.com/insight/the-unseen-grind-a-visit-to-apples-durability-lab/

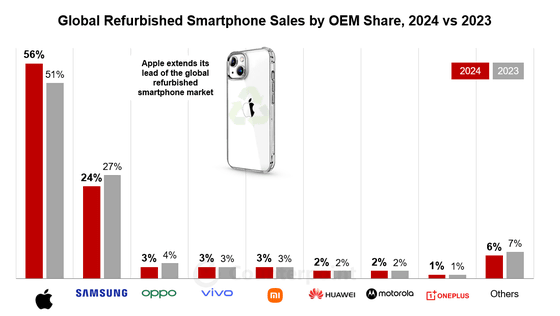

Counterpoint points out that Apple puts great effort into testing the durability of its products, such as the iPhone, and as a result, refurbished iPhones retain their value 40% higher than Android smartphones on the market. Apple is also known for delivering software and security updates longer than Android. Counterpoint points out that these factors have allowed Apple devices to remain popular even when used or refurbished.

In fact, the iPhone accounts for more than 56% of the global refurbished smartphone market, and Counterpoint noted that other Apple products such as Macs, iPads, Apple Watches, and AirPods are also performing well in the refurbished market.

Counterpoint, which visited the durability testing lab that supports Apple products, which are highly popular in the refurbished market, has revealed the details.

◆Environmental testing

Apple creates worst-case environmental scenarios in its laboratories and devices around the world. Because Apple products are sold in more than 175 countries and used in a wide range of environments, Apple's environmental tests simulate high humidity and temperature environments and expose Apple products to these environments for hours. According to Counterpoint, Apple's environmental tests include 100 hours of salt exposure, exposure to high-intensity light, and exposure to Arizona desert dust. This is to analyze what happens if fine grains of sand get into the iPhone's speakers or charging port. In the case of AirPods, there are also tests of exposure to artificial sweat and earwax, and these tests are further adjusted to take into account some of the device usage data that Apple has access to. Counterpoint pointed out that these highlight Apple's complex efforts to adapt to changing environments.

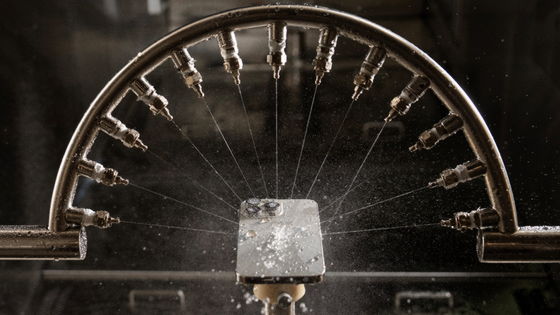

◆Liquid/Water Test

Apple offers

In the IPX chamber, the test begins with a basic ceiling drip test to simulate rain and water intrusion. Next, a test is conducted to simulate water pressure sprayed on the four corners of the product. If the product passes this test, it is deemed to have IPX5 waterproof performance. Next, a test is conducted to spray high-pressure water from a long distance. If the product passes this test, it will achieve IPX6 waterproof performance. Finally, a pressurized tank is used to simulate water depth, testing whether the product can withstand immersion in water up to a depth of 1 to 6 meters, resulting in an IPX7 to 8 waterproof performance. Other tests include immersion in various liquids such as sunscreen, perfume, carbonated drinks, and juice.

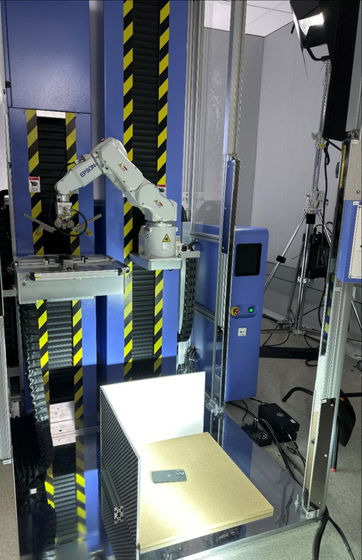

◆Drop test

According to a Counterpoint

◆Vibration test

In vibration testing, various products are subjected to vibration at different frequencies to reproduce the vibration environment and shocks that the products may experience during transportation and other real-world environments (including motorcycles from various manufacturers). The products are fixed to the vibration table for long periods of time and exposed to various frequencies.

After touring Apple's durability testing laboratory, Counterpoint said, 'I was struck by two things. First, durability and repairability can lead to design dilemmas. Products designed with durability in mind are not necessarily easy to repair, and vice versa. However, durable devices are more likely to use less material in the repair cycle and be used for a longer period of time, which can have a positive impact on sustainability. In an ideal world, both repairability and durability would be at the core of a circular economy. Another thing that impressed me was Apple's attention to detail in every aspect, from individual products to advanced machinery and testing methods. The large-scale testing of at least 10,000 iPhones before launch speaks to the depth and breadth of Apple's commitment to quality assurance. '

Related Posts: