Amazon unveils tactile warehouse robot 'Vulcan'

Amazon has announced that it has developed a new warehouse robot called ' Vulcan ' that can 'feel' some of the products it touches. Vulcan is a two-armed robot that can use force sensors to detect contact with objects, rearrange products in the warehouse with one arm, and check and grab products with the other arm.

Introducing Vulcan: Amazon's first robot with a sense of touch

Amazon debuts a warehouse robot with a sense of 'touch' | TechCrunch

https://techcrunch.com/2025/05/07/amazon-debuts-a-warehouse-robot-with-a-sense-of-touch/

Amazon unveiled the Vulcan at a technology exhibition in Germany. Amazon has previously developed a number of robots that can lift objects, but the Vulcan's biggest feature is that it can detect contact with objects.

'When you flip a coin, your hearing helps you determine which way it bounces, while your vision helps you pinpoint where it is. Then, for the final, crucial movement of picking it up from the ground, you rely on your sense of touch to decide exactly when to clasp your fingers and when to toss it in your pocket,' Amazon says.

You can see how Vulcan actually works in Amazon's warehouse in the following movie.

Meet The New Amazon Robot That Can Feel What It Touches - YouTube

Amazon's fulfillment centers maximize efficiency by storing inventory on shelves that are carried by robots. The shelves are divided into small sections, each of which can hold an average of 10 items. However, the task of removing inventory from a section of the shelf and storing new inventory has traditionally been difficult for robots to handle.

Vulcan knows when it touches an object and how much force it is applying, so it can handle the product without damaging it, making it possible to move inventory items in and out of narrow shelves.

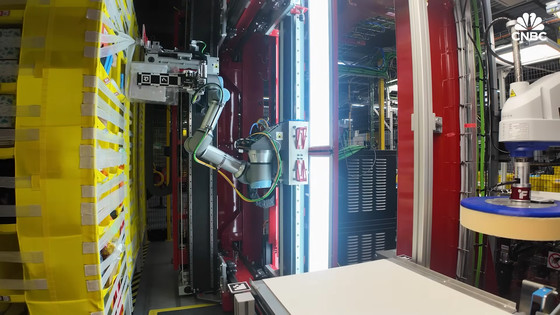

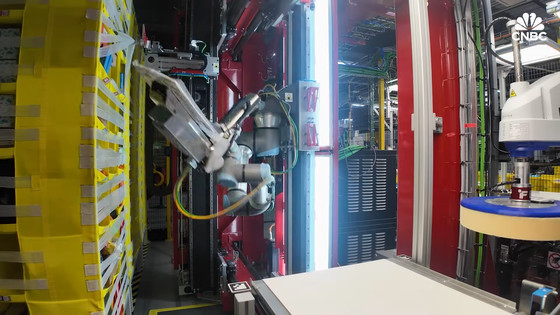

These are the arms of Vulcan that are used to grab products and put them on and off the shelves. They can grab products with a hand shaped like a large clip, and push or pull products on the conveyor belt inside. There is also a type that can grip products by suction cups instead of by clips.

Vulcan uses one arm to lift a rope divider attached to a shelf. The clip-like arm grabs the product and gets ready. In fact, Vulcan's arm is equipped with a camera, which allows it to check the shelves in advance and identify the products that need to be restocked and where they can be restocked.

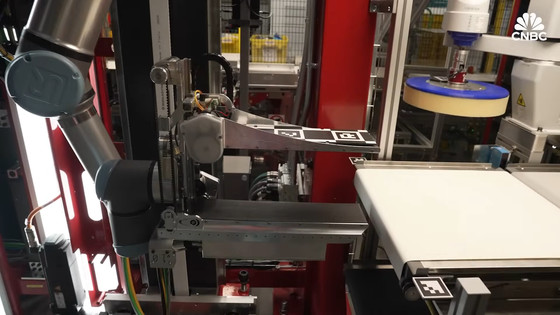

A plate-like part pops out from the clip-like arm and moves the products on the shelf.

The gap is then filled with the grabbed item. The plate and clip are equipped with force sensors, so the shelves can be replenished with stock without damaging the products.

Vulcan will be able to handle up to 75% of the 1 million products sold by Amazon. AI will determine how much force it uses to grab the product.

'The development of Vulcan was inspired by the realization that employees were wasting time on ergonomically inappropriate and inefficient tasks,' Amazon said.

Amazon says Vulcan will be gradually rolled out to fulfillment centers across Europe and the US.

Related Posts: