What are the challenges of producing a 'Made in America' iPhone?

Apple has long maintained that it is difficult to manufacture iPhones in the United States, but the Trump administration has publicly stated that

Apple can't make the iPhone in America

https://appleinsider.com/articles/25/04/10/us-iphone-productions-main-challenge-is-a-century-of-big-business-labor-decisions

On Tuesday, April 8, 2025, White House Press Secretary Caroline Leavitt reiterated her view that 'American products, including iPhones, can be made in the United States.' Leavitt cited Apple's plan to invest $500 billion (approximately 72.7 trillion yen) in the United States over the next four years, which it announced at the end of February 2025, as an example, saying, 'If Apple didn't believe it could be manufactured in the United States, they wouldn't invest this much money.'

The Trump administration reiterates that 'iPhones can be manufactured in the United States,' despite Steve Jobs and CEO Tim Cook repeatedly stating that 'manufacturing in the United States is difficult' - GIGAZINE

The Trump administration believes that the United States has the funds and labor to produce iPhones and other products, but AppleInsider points out that this is not the case. This is not just an issue for Apple, but a problem for manufacturing, especially electronics manufacturing, in general.

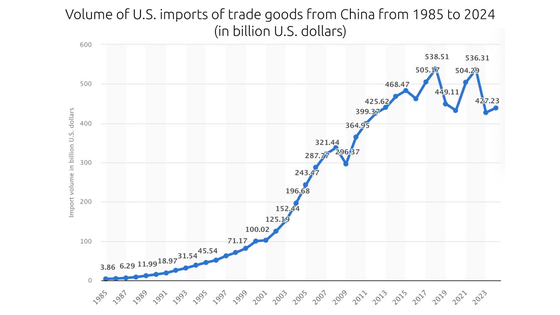

Below is a graph summarizing the total value of trade imports from China from 1985 to 2024. The total value of imports from China was $4.77 billion (about 680 billion yen) in 1986, but 10 years later in 1996, it had more than 10 times that amount, $51.51 billion (about 7.37 trillion yen), and in 2018, it had further increased by more than 10 times to $538.51 billion (about 77 trillion yen).

The modern trade relationship between the United States and China was established in the 1930s. At the time, the United States aimed to sell its own products to China, not buy from China. However, the outbreak of the Second Sino-Japanese War in 1937 made trade difficult. Over the next decade, China advocated for communism, and the United States experienced the Cold War and the Korean War. In 1950, the United States imposed a strict trade embargo on China.

It would take another 20 years for tensions between the United States and China to ease, but things started to calm down in the 1970s. Chinese products slowly began to flow into the United States, and American companies realized China's advantages. China's advantages were 'overwhelmingly low-cost labor.' Container shipping was also booming at the time, which was a tailwind for China.

Some workers, such as textile workers, protested against cheap Chinese products from an early stage, but by the 1980s many American companies, including Apple, had begun outsourcing parts of their operations to China.

Throughout the 1980s and 1990s, most of Apple's products were still made in the U.S. However, in the late 1990s, Apple began to develop a fortunate relationship with Foxconn that would eventually lead to where Apple is today. Foxconn is the world's largest electronics manufacturer, with 12 factories across China. About 95% of iPhones are assembled in China, with Foxconn's share of the assembly reaching about 70%.

During Apple CEO Tim Cook's visit to Foxconn's Zhengzhou Technology Park (iPhone City), the factory employs around 120,000 people, a number that is set to grow to 200,000 by 2022.

by iphonedigital

Foxconn is not the only foreign company with which Apple has close ties: Taiwanese company TSMC also manufactures semiconductors used in Apple products, and business with Apple accounts for about 25.2% of TSMC's annual revenue.

TSMC has a factory in Arizona, USA, but it will only start producing chips there in September 2024. Therefore, most of Apple's silicon is still manufactured in TSMC's factories in Taiwan.

South Korea-based Samsung Display is a major display supplier for the iPhone and iPad. Although it is a South Korean company, it has production plants in China, Vietnam and India.

As such, almost all of Apple's supply chain is connected to countries that have been hit hard by the Trump administration's reciprocal tariffs (commonly known as the Trump tariffs).

Therefore, AppleInsider points out that Apple is 'not going to withdraw' from China. In fact, Wedbush analyst Dan Ives told CNN that it would take three years and cost about $30 billion for Apple to move its global supply chain to the United States.

Another problem is that even if they move production to the United States, they cannot hire labor at the same low cost as they can in China. Foxconn pays its average factory worker about $3 an hour. Factory workers are required to work 10 to 12 hours a day, so the average daily wage per person is $30 to $36.

On the other hand, the United States has a federal minimum wage ($7.25 per hour), so even if you work 8 hours a day, you can earn $58 a day. If you want to work 10 to 12 hours a day, the factory has to pay an additional $21.76 to $43.52 in overtime. In addition, AppleInsider pointed out that some states have state wages that exceed the federal minimum wage, so workers' wages could jump even higher.

That means that if Apple were to move production to the U.S., it would have to compromise on either wages or working hours. However, AppleInsider points out that 'No one in the U.S. is going to assemble iPhones for minimum wage. It's probably hard to find workers for even $15-20 an hour.'

In addition, East Asia has a cultural characteristic of 'expecting a lot' from even average workers. In fact, Vietnamese workers were asked to live in factories during the COVID-19 pandemic in 2021, and it became a hot topic when they slept in tents inside the factories.

'We will see the biggest job revival in American history, with workers coming to work in high-tech factories,' Trump's Secretary of Commerce Howard Lutnick

In addition, Secretary of Commerce Lutnick said that American iPhone factories will be 'automated,' but the actual production and assembly of iPhones is largely unautomated. Apple has plans to promote automation with the goal of reducing the number of workers in its factories by 50%, but this has not been realized at the time of writing.

AppleInsider also points out that the United States has an ugly habit of labeling manual labor as low-skilled. However, Apple CEO Cook does not see Chinese factory workers as low-skilled, but rather as having highly specialized skills.

While many countries devalue vocational training, in China it is not considered an 'inferior path.' Factory workers are still considered valuable, which is why China has lots of tool engineers.

On the other hand, the United States does not have many highly skilled tool engineers like China. 'Most people don't even know what a tool engineer is,' AppleInsider points out.

'Apple products require very sophisticated tooling. We need cutting-edge precision in the processing of tools and materials. And China has the tools manufacturing capabilities to do so well,' Cook said in a past interview. 'If you had a meeting of tool engineers in the U.S., I don't know if you could fill the room. In China, you could fill several football fields.'

Tool engineers are a highly specialized profession that is somewhere between a craftsman and a traditional mechanical or electrical engineer. It literally takes a generation to acquire the skills that Apple needs, and Apple has 'honed its engineering skills for decades' by producing iPhones in China, AppleInsider points out.

While there is a good chance that Apple will open a factory in the US, 'it's not as simple as just telling them to do it,' AppleInsider noted.

Given this, AppleInsider points out that 'even if Apple could provide sufficient wages and secure workers in the US, US factories would still be producing products slower and of lower quality (compared to Chinese factories), at least until Americans start turning to these types of jobs.'

Furthermore, even if the iPhone could be produced in the United States, the fact remains that the selling price of the iPhone would likely be exorbitantly increased. 'It's unlikely that the price would jump to $100,000 per iPhone, but with the 145% tariffs on Chinese goods, the shortage of American labor, and the time and cost required to build up production capacity, it's entirely possible that the price could rise to $3,000 per iPhone,' AppleInsider points out.

Related Posts:

in Hardware, Smartphone, Posted by logu_ii