A report on a legendary trapper's incredible technique for cutting up deer meat at breakneck speed

Mie prefecture has created a strict manual for the processing of deer meat, and venison that is handled in accordance with the manual is certified as '

Mie Prefecture | Gibier: Spirits

https://www.pref.mie.lg.jp/CHISANM/HP/foodinnovation/85101045286.htm

Mie gibier is served at many restaurants, mainly in Mie Prefecture, and processed foods made with Mie gibier are sold at several stores . When I tried the frozen food 'Venison Hamburger Steak,' which allows you to easily enjoy Mie gibier, I was surprised at how it had no animal smell and tasted very different from the venison I had eaten before. The following article provides a detailed summary of what 'Venison Hamburger Steak' is like.

I had the venison hamburger and venison meatballs cooked at a factory and tried them - GIGAZINE

To find out how they produce such high-quality deer meat, we asked Mr. Furuta, who is in charge of capturing and butchering the deer, to show us the butchering process.

We arrived at Mr. Furuta's dismantling workshop in Mie Prefecture. Dismantling is taking place in a sanitary controlled area behind the shutters.

We wash the deer and remove the organs on this yellow table.

Large deer antlers were piled up near the entrance to the workshop.

When we arrived at the workshop, a deer was hanging with its head down. The man in the back is Mr. Furuta. We had hoped to be shown the process of killing the deer caught in the trap, but it was raining on the day of our visit, and it was dangerous for inexperienced people to go into the mountains, so Mr. Furuta killed the deer early in the morning and had already disposed of it up to this point.

The methods of butchering a deer vary greatly from person to person, with some people cutting off the head and hanging it upside down for a whole day to drain the blood, and others removing the internal organs and throwing it into a pond or river to cool. However, Furuta uses a method in which he stabs a knife into the neck of a trapped deer, severing the blood vessels in the heart and draining the blood at the right speed, and butchers a deer caught in the morning in the morning. The technique of 'killing a deer by cutting the blood vessels in the heart with a knife' is apparently unique to Furuta in the world, and this method of draining the blood allows him to produce deer meat that is completely free of any animal smell.

The dissection work had to be completed by the morning, so Furuta worked briskly while giving explanations. Here, he uses an electric saw to split the deer into left and right halves.

I also recorded a video of the deer being cut up with an electric saw.

It was neatly divided into left and right.

The cut surface looks like this. It cuts straight without any misalignment.

Once you've done this, clean the floor.

Then, they throw away the white coat they were wearing. By replacing the white coat every time, they maintain a clean state.

The rest of the cutting process is done in a separate room in the back. Incidentally, the hangers that the deer are hung on were made by Furuta himself.

Disinfect your boots.

They enter a separate room to wash their hands and put on gloves. The room for dividing the deer into left and right halves is separate from the room for cutting the meat, which prevents bacteria from getting on the meat.

On display in the room were a certificate of completion for the Food Hygiene Manager Training Course

There are knives of various sizes available for cutting meat.

He customises the blades and handles himself to make them easier to use. He also has knives that he cuts out from aluminium and sharpens.

Some of them used deer antlers as handles.

Pliers and tweezers are also provided.

This is a sterilizer for sterilizing knives.

Move the venison onto the workbench.

Place on a cutting board.

The other one will also move.

Here you go.

This completes the preparation for cutting.

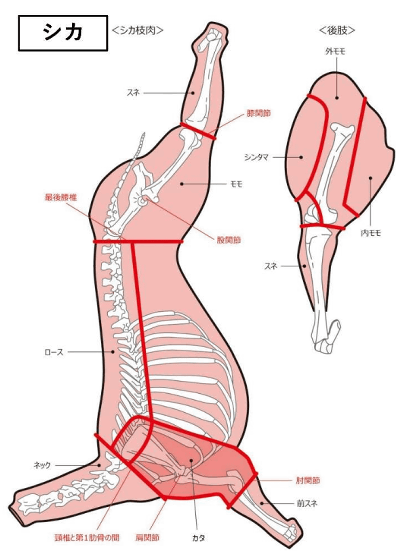

For reference, below is an illustration of the names of different parts of the meat listed in

First, the blade is inserted at the junction between the body and the hind legs to separate the legs. Furuta says, 'Even with my eyes closed, I know where to insert the blade.'

The leg came off in an instant.

Cut the tendon.

Then remove the meat from the bones.

This is thigh meat.

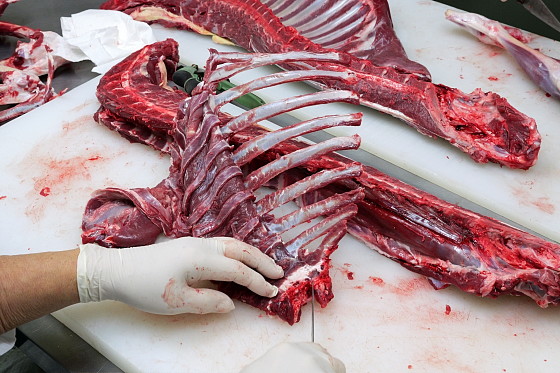

Here's what it looks like at work. Mr. Furuta knows exactly where the bones and joints are, and cuts them up quickly without a moment's hesitation.

The ribs were severed with a snap.

It is divided into a spine section and a rib section.

Next, insert the blade between the rib bone and the meat.

While explaining the work, his hands moved at an incredible speed.

The rib came out nicely.

This is pork belly.

Next, cut away the meat around the spine.

This is fillet meat.

Cut the loin into pieces as well.

The loin is large.

Run the knife along the backbone to carve out small pieces of meat.

We were able to salvage a significant amount of meat off-cuts.

The cut meat is packed into a tray.

The inedible parts such as the tendons are used as chicken feed.

The remaining bones can be boiled to make a delicious soup.

The cut meat looks like this when spread out on the table. The cutting work was completed in about an hour.

All that's left to do is check to see if there is any metal mixed in and the job is complete.

If a deer is killed with a gun, the edible portion is reduced, and if it is caught in a box trap (a cage-like trap), the deer will thrash around inside, causing internal bleeding and lowering the quality of the meat. For this reason, Furuta hunts using snare traps, which have less of a negative impact on the meat. Furuta's deer meat is thoroughly drained of blood, so there is no animal smell. Furthermore, strict hygiene management prevents the introduction of germs, and the meat can be aged for a long period of time. For this reason, Furuta's deer meat is purchased by request from top restaurants all over the country.

Furuta has been introduced as a 'legendary trapper' on TV shows and gourmet magazines, and during our interview he revealed a lot of amazing information, such as 'Just by looking at the mountains while driving on the highway, you can tell where the animal trails are,' 'He uses traps that he developed himself,' 'He can even calculate which of the deer's four legs will be caught in the trap,' and 'He stabs a knife from the deer's neck toward the heart, precisely cutting the blood vessels in the heart to drain the blood.' So, we plan to publish an article summarizing Furuta's secrets of deer hunting and the significance of eating deer in the near future.

Related Posts: